20 Carlton House Terrace

Erith Contractors appointed Swanton Consulting to provide the required temporary works designs to complex cut and curve works at 20 Carlton House Terrace project. The main temporary works included the design of a stability bracing, multilevel slab propping, temporary building support to the basement, Tower Crane on top of the existing columns, demolition sequencing, transfer structure jacking, basement propping, basement column assessment, external tower crane based on RC columns.

The existing development consisted of two buildings office and residential blocks based on the common basement (approximately 11m deep). Re-development happened only in the office and basement. Residential building was occupied throughout the works.

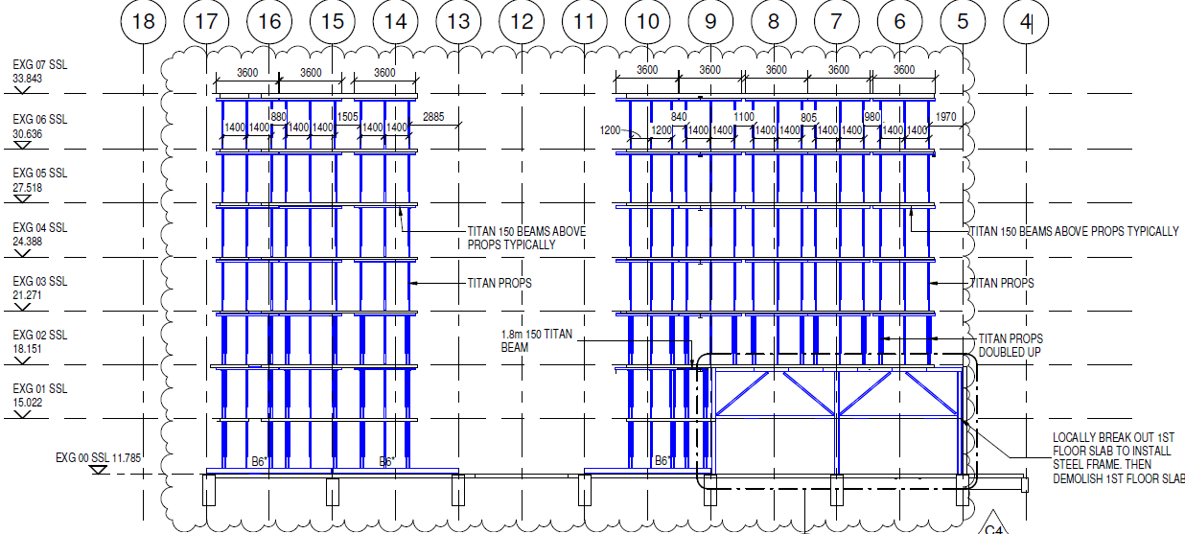

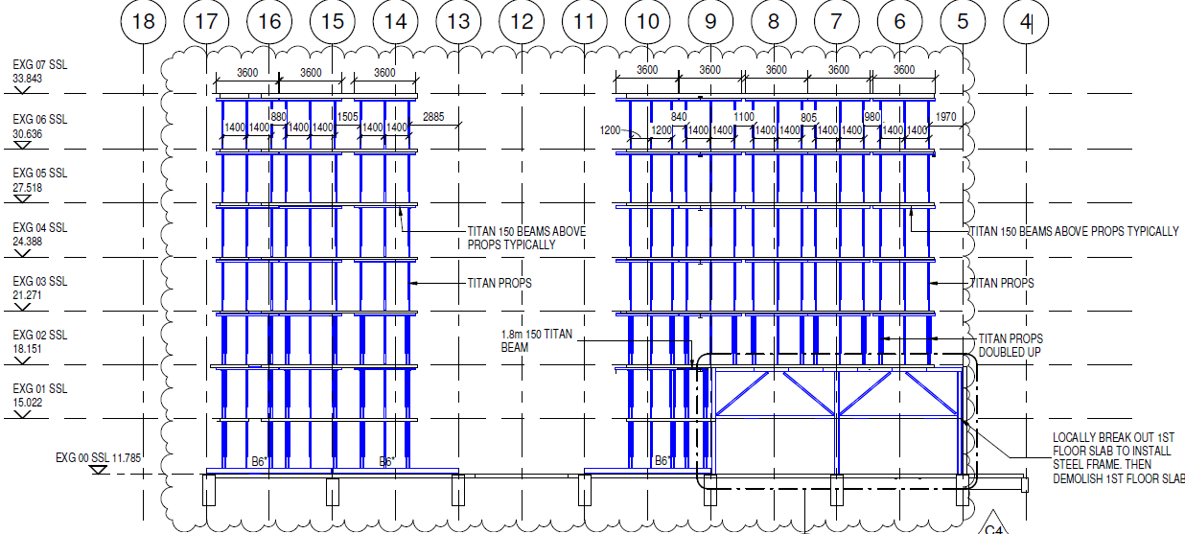

Multilevel Slab Edge Propping

One of the big design elements for the job was slab edge propping. The existing slabs during demolition were losing permanent support and required temporary support measures. This was applied from level 7 to ground floor. TITAN system propping was used with a single line of props. The main advantages were easy installation and manual handling. Additionally, to slab propping, some RC beams were propped as well. Part of the propping was changed to the steel frame where the level 1 slab was fully removed, and double height space was created. Steel frame was designed in that space.

Stability Bracing

In the temporary stage the existing building was split into the concrete and steel frame parts. Each of the remaining building required temporary stability measures as all the existing cores were demolished. In the concrete section RMD frames were utilised. Steel building was braced with X brace system, welded to the existing columns.

Tower Crane 1 Base

Logistics around the site were much restricted in the first phase of the works, which has limited the possible tower crane locations. The best position was on the existing GF slab. Swanton has designed steel base that bridged load form the ballasted base to the existing columns and diaphragm wall. Additional propping between GF and top of the retaining wall was designed utilising RMD Megashores. Tower carne was moved to the grillage on top of the new core when it was finished. It included designing cast-in anchors to the core and additional reinforcement around them.

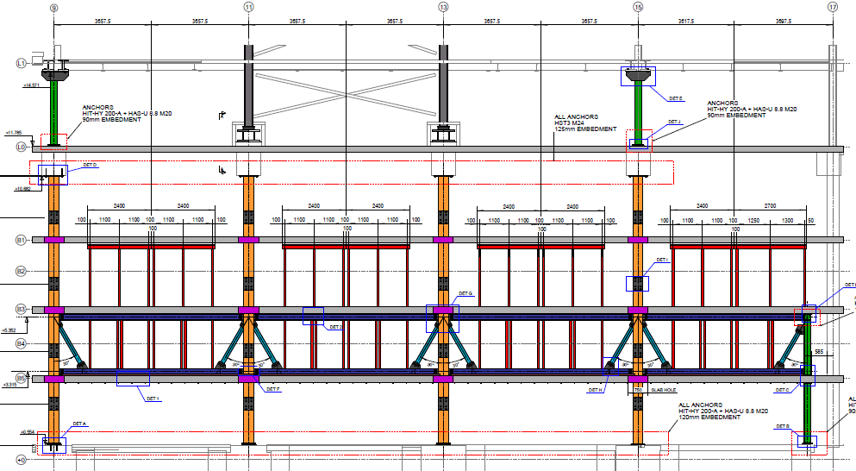

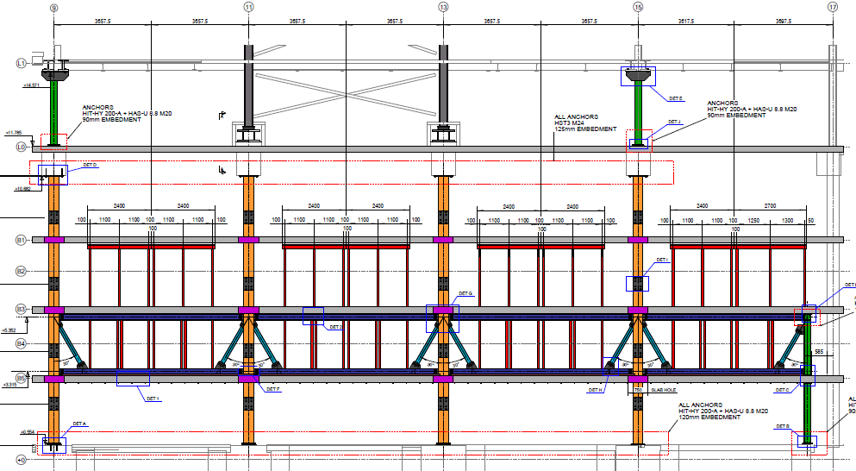

Vertical propping drawing

Steel Building Propping (Foundation to Ground Floor Beams)

New cores were clashing with the existing columns that supported the steel portion of the remining structure. Demolition enabling works included design of the temporary support. The proposed structure was not only propping the remaining building above the GF but as well free edge of the basement slab. The proposed solution included steel truss element with TITAN props incorporated in between beams.

Tower Crane 2 Base

Additional Tower Crane was required for the build stage of works. It was located outside of the existing basement but very close to the existing access point. Hence, the base of the crane was above the ground level. Swanton designed concrete columns and pile bases below them. The solution allowed machines passing below the Tower Carne Base.

Basement Propping

The existing basement wall was built as a 609mm thick slurry wall. Buttress walls every 3.8m perpendicular to the ground retaining wall were provided as the wall construction method did not allow for continuity of the reinforcement. Existing basement slabs were supported only on the buttresses, hence providing limited support to the retaining wall. Complex 3D FEA model was created in Dlubal RFEM. It allowed demolition of the basement slabs with propping limited to the southeast and southwest areas where all slabs were removed. Propping compromised of steel UC props anchored to the existing wall.

Basement Column Assessment

Existing columns in the south part of the basement were steel welded section encased in concrete. Encasement was for fire protection. Swanton did a detailed analysis of the columns utilising the existing basement 3D model. The focus was in assessing the increased buckling length using the stabilising effect of the encasement. The assessment reduced by 70% column bracing requirement.

Other temporary works included sequencing of the demolition around the northeast core. Swanton has produced demolition sequence document and provided design of the RHS column. The proposed element was later incorporated into the permanent concrete wall.