120 Fleet Street

Erith Contractors appointed Swanton Consulting to provide the required temporary works designs to allow for the demolition and piling works at the 120 Fleet Street project. The main temporary works included the design of a basement propping scheme, stability analysis, assessment for early hydro demolition works, the design of a retaining wall and the design and sequence for a moving propping tower to allow the roof demolition.

The existing development consisted in two buildings: the Rivercourt building, which was fully demolished, and the Daily Express building, which is a Grade II* listed building that remain. The Rivercourt building was a ten-storey plus two basement levels building formed of a steel frame structure with steel cores and composite slabs. The building had concrete retaining walls and raft.

Daily Express building archive picture and historical elevation showing concrete portal frames.

Daily Express Stability Analysis

The Daily Express building was built in the 1930s and went under major modifications is the 1990s. The original structure comprises concrete ribbed floors spanning between concrete single span portal frames. These portal frames provide lateral stability on the East-West direction. During the 1990s development, a new concrete core was built from Ground Level to Roof and an expansion joint was included, making the building globally stable above Ground Floor. However, the lateral stability below Ground Floor in the North-South direction was dependent on the Rivercourt building. An assessment was done to verify the building could stand without the need of any temporary works by considering the slabs as props. The shear at the interface was assessed and verified with the existing reinforcement, to prove no temporary works were required for global stability.

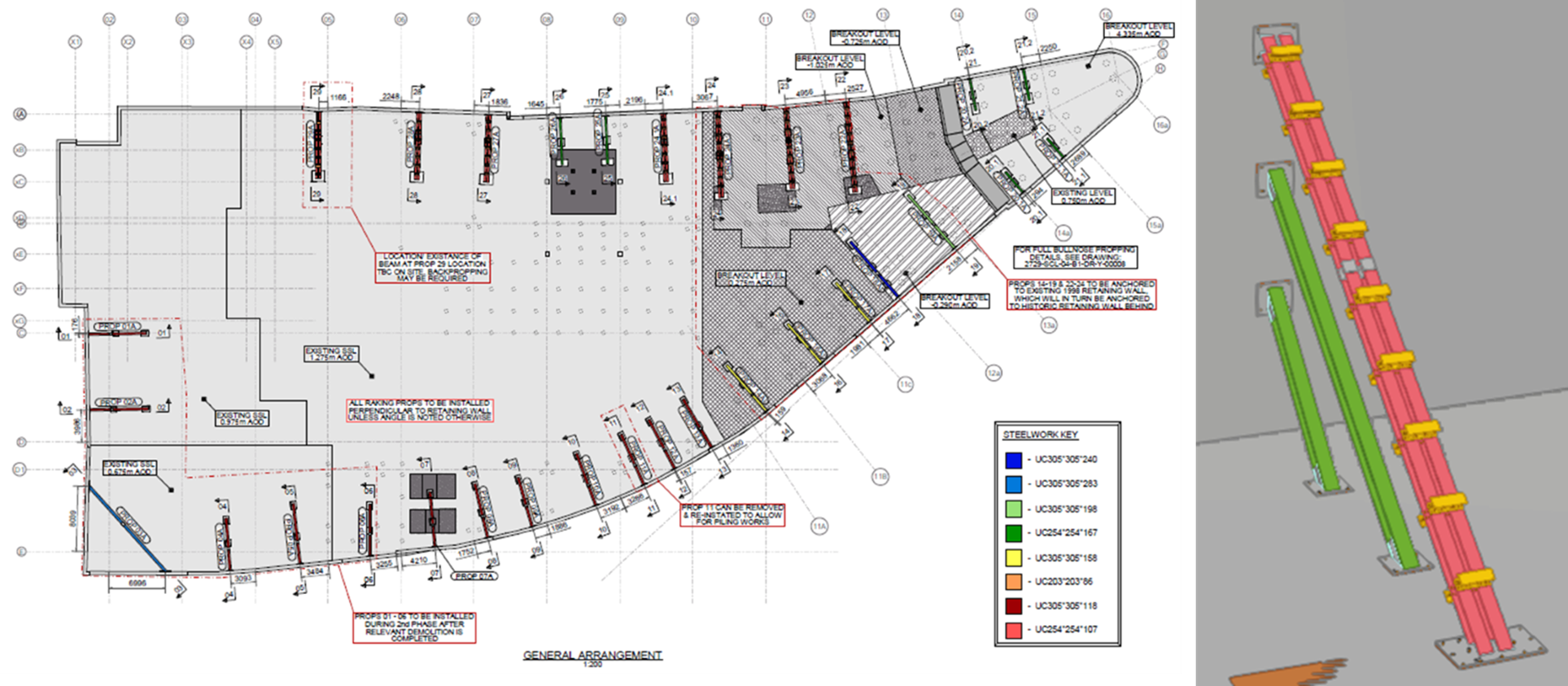

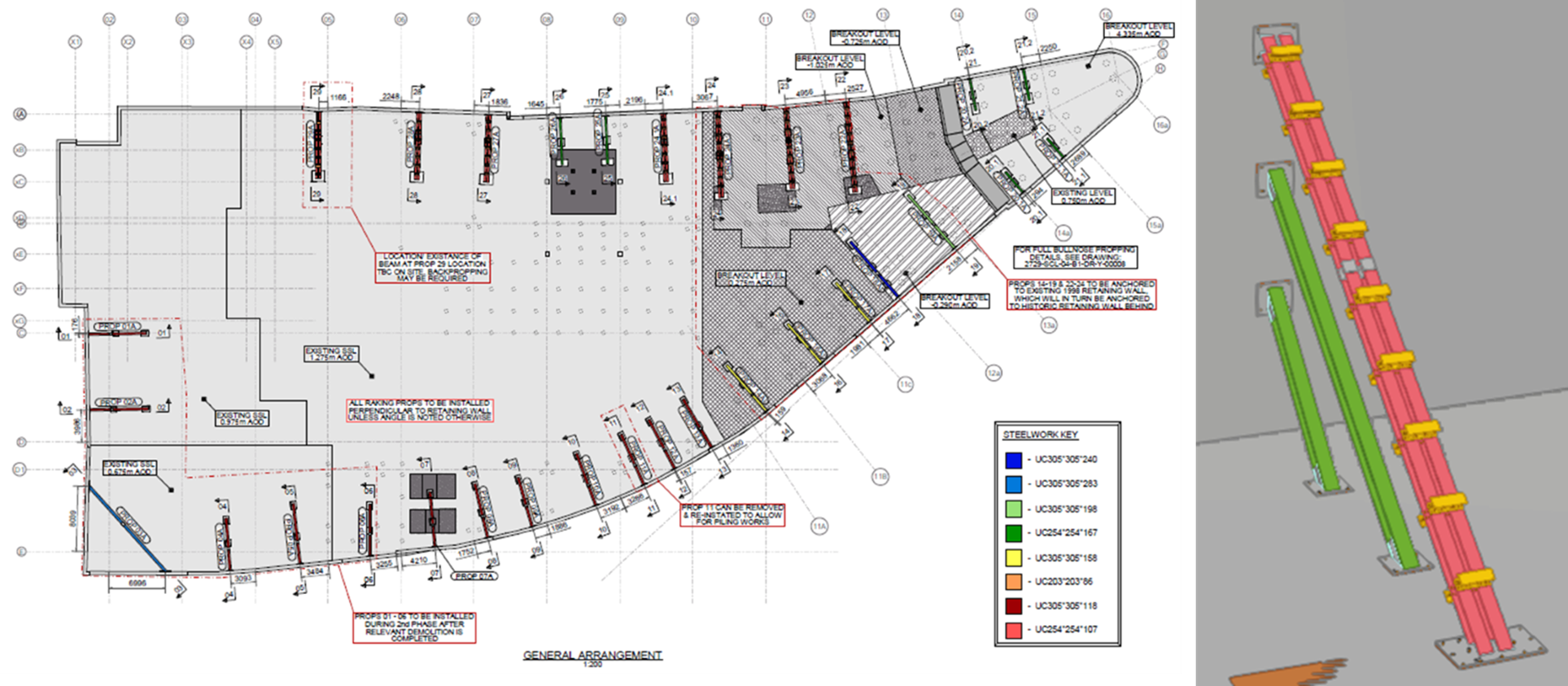

Propping plan view and 3D model example prop.

Basement Propping Scheme

A temporary propping basement scheme was required to laterally support the existing retaining walls at B1 and GF level. The props were fabricated using the building’s demolition steelwork. These was possible given the age of the steel (25 years) and the number of available section over a length of 9m, which allowed to design long props without the need of a high number of connections. Some sections were design as built-up sections from smaller profiles to increase their structural behaviour, as not enough large sections were available. The built-up sections were battened together using pieces of reused beams. The geotechnical and global analysis on the wall was done with Plaxis FEA. From it, the props’ design loads were obtained so appropriate sections were design using an FEA software. Additional thermal and accidental loads were also considered for the design.

In a later stage, due to the steel being reclaimed, imperfections on the sections were present which could affect the props’ behaviour. A more refined analysis by modelling the as-built prop as plate elements and undertaking a stability/buckling check allowed us to verify the props suitability under a stress analysis.